Blog

Lean Management Systems as a Culture

MAY 2014

Despite that the transformation procedures of the lean management systems constitute a systemic change; it can only be successful if there is a cultural change within the company. For that reason, it is crucial that a culture transformation occurs in the transformation procedures of the lean management. Well then, what is culture? How can we define it?

Social scientists give the general definition of “Culture”, as follows:

“It is an entity, bearing the features of being natural and living as it is the common living organization of a community being a social organization, as a whole bearing the characteristics of changing, developing and renovating in the time. It does not own a static, but a dynamical structure. It originates and develops in relation with the living organization of a community. For that reason, it is not outside life, but inside. ”

In a similar way, we can define company culture. In other words we can say that the common work in a company is a dynamical entity owning the characteristic of being a living organization renewing in the time depending on the people. In the transformation procedures of the lean management system, culture ensures a change towards the lean thinking of culture inside the company by using this dynamical continuous changing and developing structure. The culture conveyed by the employees of the company has an influence on the culture of the company. Here we are considering culture as the common culture composed by the company vision, mission, objectives and internal applications. In general culture of the company is in big part the reflection of the boss of the company and of the executives. This is the reason why it is necessary to begin the change of culture in the transformation procedures of the lean management culture by the company associates and executives.

The transformation procedure begins when the company associates and the executives determines that their company common culture with a culture conception in parallel with lean management systems. In most cases, people working in the company have different cultures. To be successful, the company must ensure that a culture is constituted by melting the different values of the people coming to the company to work into common values toward a common objective. This culture must include various values as team work, focus on performance (productivity), work safety, employees’ health, environment conscience (respect of people and environment), importance of the service and product quality, focus on client, etc. These common values include the prosperity of the company and the improvement of employees’ social and financial resources linked to this prosperity. It is only in a successful company (with continuous profit making, developing and growing) where importance and confidence is given to the employees that employees put forth the effort of constituting a common culture and set to develop and make it grow. This is why when you are referring to lean culture in companies, it is necessary not to put aside the company prosperity and the importance and confidence given to the employees.

The people working in the company are living in society, whose culture significantly influences the company culture. The more the society where employees live gives importance to values as environment, nature, human health, operating safety, hygiene, saving, etc, the higher the employees culture level is. There are great differences between the employees of the societies, which completed well before us industrial revolutions, and our employees in terms of work safety, environment and productivity awareness. In DuPont factories, working for two centuries, you can find factory workers families, working for 5-6 generations, having adopted the company culture as a style of life where the culture of developing work safety and human health is passing from father to son.

It is a pity to see one again after we lost 301 workers (our soul) in the Soma Mines that the work in these mines show us how remote we are concerning work safety and worker health. This disaster must not be considered like a situation of exception. If we study mortal work accidents in Turkey throughout the years, we can see that in some years, the figure was at least as higher as the figure of this last event. We can also notice that there is also a much higher number of workers become disabled after work accidents. Radical decisions and supporting legal framework must immediately take with efficient controls for the culture of work safety and worker health as a war of liberation and it is quite clear that an overall cultural change and transformation of the society is needed.

Lean culture does not only include only the production and service units like productivity, work safety, workers health, environment awareness, saving awareness, product and service quality, it also includes all the units of a company. Therefore, to change culture, it is not enough to apply lean management systems to only service and production units. Lean culture must include all the processes of the company, beginning from the purchasing process to the selling process. And the company will be even more successful if it can expand this culture to its providers and clients.

A change (transformation) of the company culture means a change in our style of life, point of view and work organization within the company. We can even go further by saying that it means that lean culture must expand to all our life. Even if you work for the transformation of all the working and management systems in the company by lean managements applications and systems, these transformations, after a certain lap of time, will show tendency to go back to the previous situation, that is to say to the previous company culture. For this reason, we need to know that it is necessary to understand that the transformation procedures of the lean management system are a real cultural change and that the systemic changes must be supported with lean cultural formations in order to constitute a lean culture.

Quality Data Collection and Standard Operating Procedures

APRIL 2014

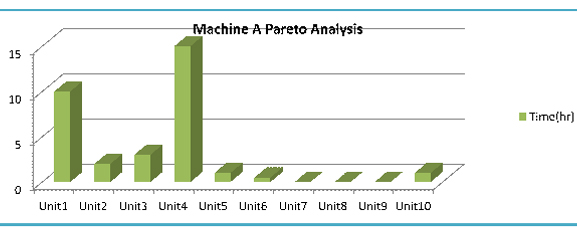

While development and improvement are performed in firms, it is required to determine existing situation and data and statistical information are needed. Why those information are required? Consider a machinery or process and assume that this machinery or process consists of 10 units (steps). We will need data to understand which unit of this machinery-process has more failures – interruptions and in order to develop and improve. If development and improvement starts from most important problem, development and improvement will be more considerable. Even the aim is to solve and eliminate reasons of all interruptions of machinery-process, eliminating the most important problem will always provide us a considerable advantage. Namely, in order to be able to measure whether development, improvement is available or its quantity, we need existing and previous data.

Importance of having data and statistical information in development, improvement activities to be performed is equal to correctness and quality of these data. Quality of data covers time factor and standard work in addition to correctness of data. Receiving instant standard data, information, performing assessment based on these information will accelerate our development and improvement activities. Effect of solution will be important since we handle and solve correct problems.

So, how can we create quality data in our businesses? Creating high quality data and collection of these data is a combination of two stage operations. Initially, we should create Standard Operating Procedures (SOP – Standard Operating Procedure). Standard Operating Procedures are documents which expressly describes how, when, whom the process in a business and each step of this process will be performed. A certain standard for each work performed in a business should be maintained and this standard work should be performed in the same way by everyone. If two different operator performs a setting (a work change) work of machinery through different ways, consequently times to be spent for this work will also be different. Even though we cannot eliminate this change in works dependant on human, it is possible to minimize them with Standard Operating Procedures. Even people work under Standard Operating Procedure, differences arising from personal differences (slow working, distractibility, etc.) will create small differences. Without Standard Operating Procedure, these differences increase to 20-50% levels between operators but smaller differences such as 3-5% are seen in SOP and trained operators. When these small differences are followed and required corrections are performed, a continuous improvement towards zero will be seen in values. Briefly, delta difference occurs less in SOP applications. SOP’s are not only documents making contribution to production effectiveness, but also they are beneficial for keeping product quality and work safety under control.

Issues to be considered while creating SOP can be listed as below:

- SOP’s should be created by person/persons performing that work with a common opinion and cooperation. If there are 3 persons using this machinery, SOP of this machinery should be prepared by these three persons or at most one senior master, shift leader, etc.

- Definitions should be made in SOP step by step.

- It should be written with the simplest language possible and with brief sentences that can be understood by everyone.

- SOP’s should be visually supported with images and photographs (before-after application, correct-false application. Etc.)

- SOP should not be as very long sentences and small font sizes, each work (SOP) should be defined with 5-10 steps large font sizes.

- It should be very simple and understandable. While Standard Operating Procedures are created by operators and supervisors, warnings should be made in order to be prepared as simple as possible by engineers and managers. Except, direct SOP’s should not be prepared by department managers and higher level managers. If prepared, problems may be experienced in application processes of SOP’s within the business. SOP application either not realized or takes so much time to be applied.

- The understanding of write what you do, do what you write and make it simple should be developed for SOP in businesses.

Prerequisite of Lean Management System is Standard Operating Procedures (SOP). SOP’s should be created not only for production, but also for all operational processes within the business. Standard Operating Procedures (SOP) are important prerequisite of high quality data collection operations in Lean Management alteration-transformation processes.

Many businesses in the manufacturing processes of data collection and archiving management with collecting statistical information depends on having a process operator is working with conventional methods. In this case the information to be recorded varies from person to person. Some employees at the end of his business will record every step of the job. Some employees while taking notes in a small notebook that at the end of the shift, and some shift registers at the end of it if you have in mind what information. In some business partners and this collected data will be recorded by the official server a reporter, will be transferred.

Since these data collection works that are performed with classic methods are dependent on many workers, working time – interruption (stop) time – setting time and times consisting or planned interruptions are mixed and faulty inputs are performed. These faults arise from different attention and works of different workers. Even, times of three different failures occurring at a machine during interruption period may be different. In such case, it cannot be always possible to reach actual failure periods, setting periods, working speeds and consequently, problems. As the number of operations and number of operators performing these operations are higher, so deviations from correct information in these data can be higher.

To eliminate all these problems in lean manufacturing and management systems, data collection systems are now classics in this way are not included. Instead, and be less subject to human automatic data collection system comprising limiters are used. This system briefly automatic data collection systems (DAS -Data Automation Systems) and / or quality of data collection systems (QUDACO - Quality Data Collection) call. These systems are systems working independently from as people as possible. In business processes on the machine mounted sensors, scanners, PLCs servers and PCs consist of. Internet network connection with the machines, the process provides for remote monitoring of the situation. Working time – set up time - stopping time and scheduled downtime can be separated from each other precisely. The system is unlikely to fail at this point. Stopping time positions within the structure of the machine in some machines, depending on the amount of 100% on some machines require manual entries. In any case, DAS and / or with QUDACO system of data collection systems, data collection system based on the classic comparison is made of better quality too. DAS and QUDACO system is the most important feature of these systems is known to be instant status report.

Effect of total production amount in certain period for production businesses is very important on the cost of manufactured product. As an example, companies manufacturing 40 machineries with 120 unit/month production cost in the business have improvements in the other month and if it produces 60 machineries with the same cost, production costs will reduce from 3 unit/machinery to 2 unit/machinery.

Improving production time in development and improvement activities to be performed in Lean Manufacturing & Lean Management transformation processes, namely increasing the product manufactured in the unit time will reduce production costs. In order to maintain these development and improvements, we should know that the most important requirement in analysis and resolution of problems is the high quality data.

While development and improvement are performed in firms, it is required to determine existing. .Read More»

Mehmet SADRAZAM

Lean Management & Operational Exellence